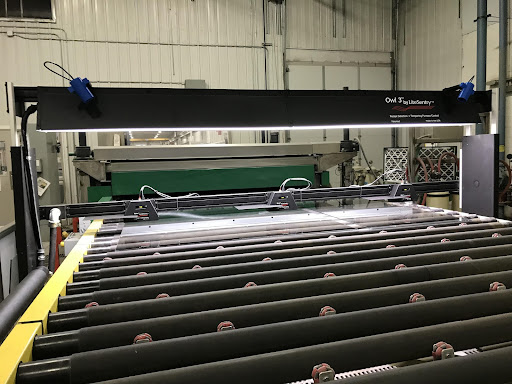

Owl 5

Glass Furnace Optimization System

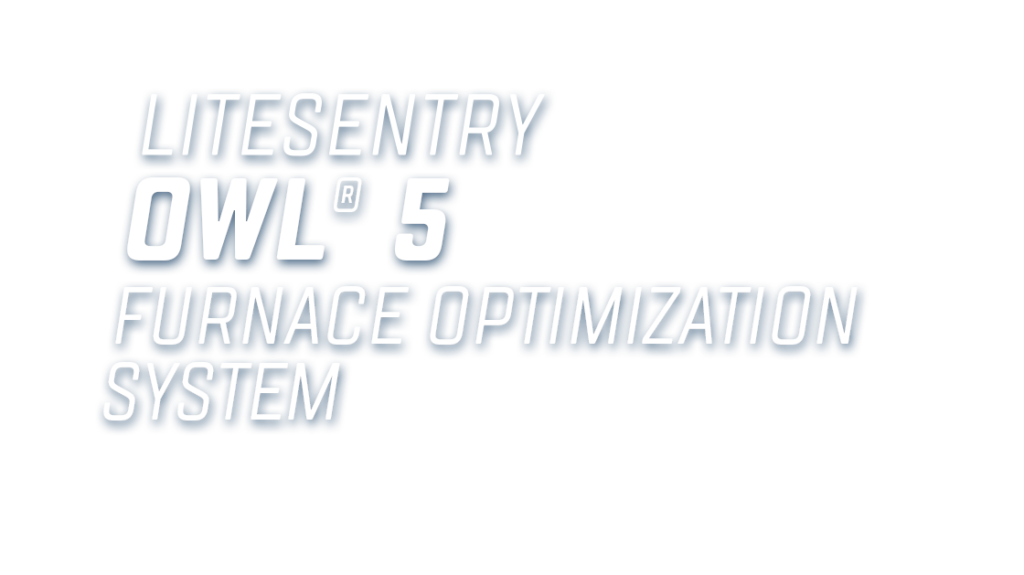

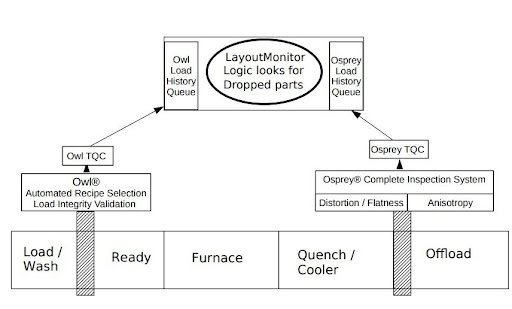

The Owl 5 transmits data to the furnace control system allowing the furnace to automatically select a recipe and optimize the heat profile, improving cycle time, minimizing distortion, and optimize flatness

Load Validator technology is included in Owl 5 OR as a stand-alone system.

With the Owl 5 Furance Optimization System, you will have your best furnace operator on every shift.

Owl 5 Furnace Optimization System

» Key Application: Tempering Furnaces

» Discern most colored glass, as well as various coating & colored glass combinations

» Automated measurement of Thickness,

» Size, Coating (LowE 1, 2, 3, i89, Non-coated), Locations of parts

» Detect faulty loads

» Real-time feedback to the furnace

» Stop conveyor in event of a fault

» Systematic and repeatable adjustments made to furnace with no operator interruption

Load Validator™ Geometry + Fault Detection System

» Key Application: Coating Line, Tempering Furnaces

» For use on critical continuous processes such as a high vacuum coating system or washer preceding tempering.

» Detect fault conditions in the glass or load geometry.

» Alarm the conveyor system to stop the glass load before the load enters the continuous process.

Proven to increase over 20%

productivity and quality!

The Owl® 5 is a patented, non-contact optical system measuring the glass thickness, type of low-E coating (1, 2, 3 silver layers, 4th surface low-E), color, glass dimensions and sheet locations as the load approaches the furnace

The system is for loads entering a batch or continuous tempering furnace.

- Conveyor begins transfer of glass. The encoder signal activates the measurement system.

- The glass enters the measurement system

- Images are captured sequentially over the full load length and width

- Thickness and low E coating information collected

- The trailing edge of the load clears the system

- Algorithms process data and transfer information to the furnace control system

- Furnace control systems adjust according to load information, and stores result in the case of a fault condition.

- Load transfers into the furnace

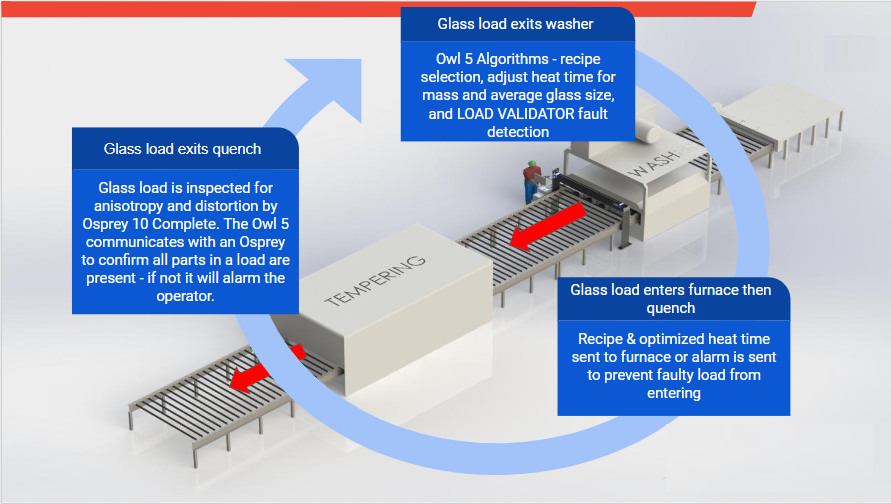

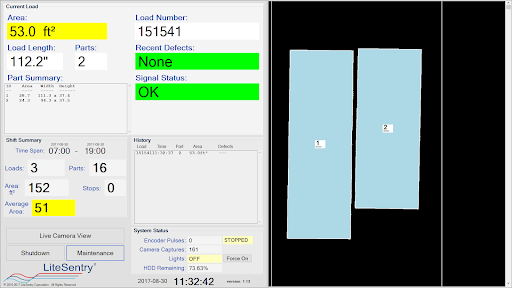

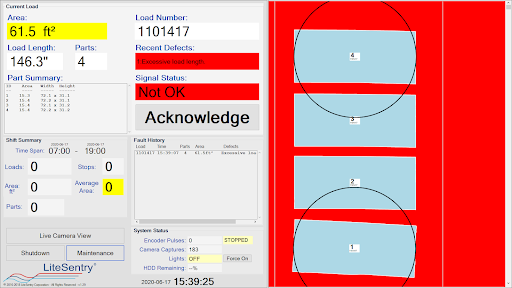

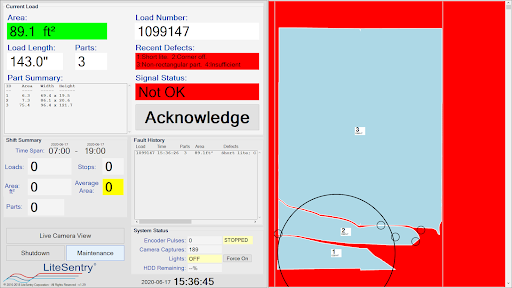

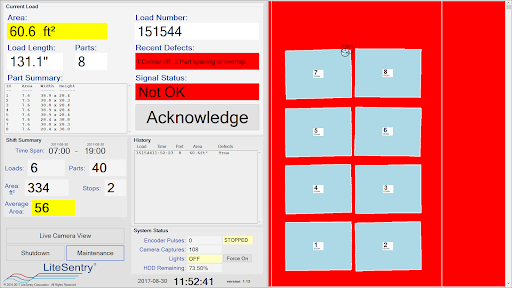

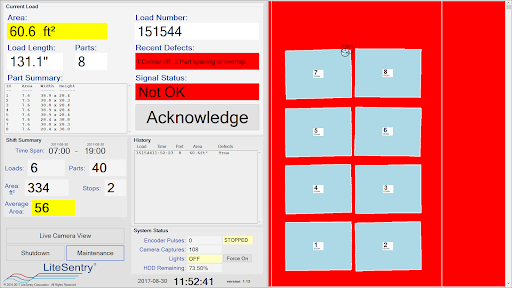

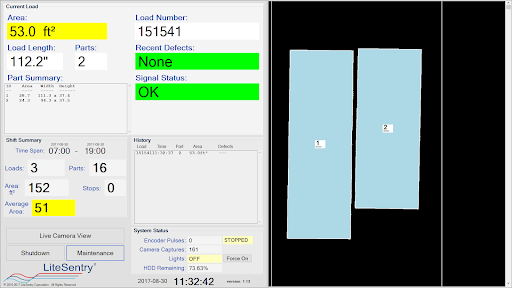

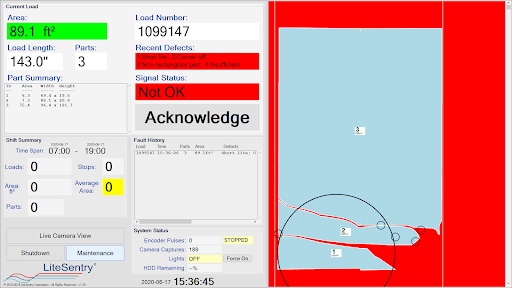

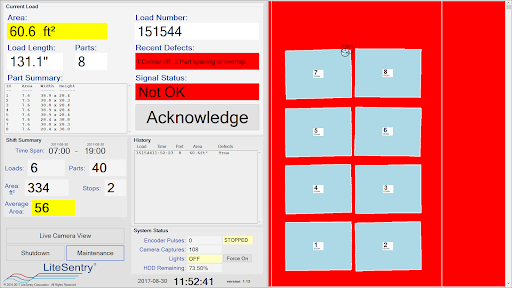

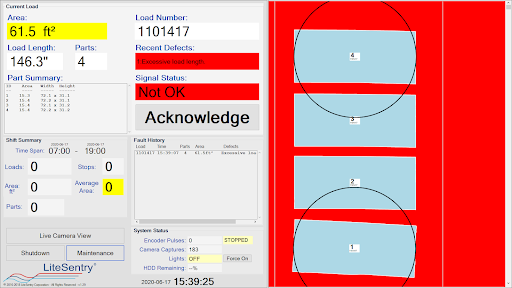

Owl 5 Furnace Optimization System HMI

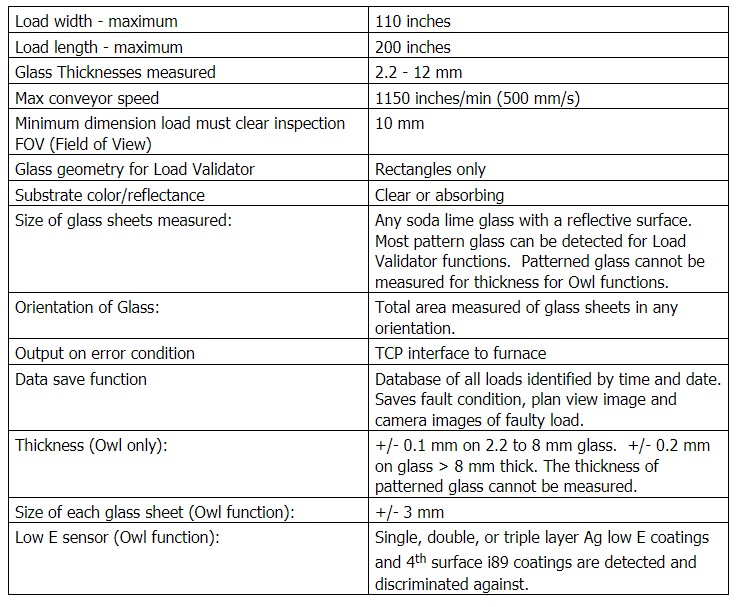

| # | CONDITION | TOLERANCE |

| 0 | NO ERROR | N/A |

| 1 | WIDE LOAD | +/- 3mm |

| 2 | PART OVERLAP | 6mm |

| 3 | BROKEN GLASS | ANY SEPARATION |

| 4 | SHORT PART | +/- 12mm* |

| 5 | MINIMUM DISTANCE BETWEEN PARTS TRAVEL DIRECTION (5a) CROSS CONVEYOR (5b) | +/- 12mm +/- 3mm |

| 6 | CORNER OFF (6a) NON-RECTANGULAR (6b) | 6mm >120mm |

| 7 | LONG LOAD | +/-12mm* |

Missing Part Notifier technology included in the Owl 5:

- Provides a check for losses in the furnace.

- The Owl 5 communicates with an Osprey to confirm all parts in a load are present – if not it will alarm the operator.

- Missing Part Notifier provides a .csv report for all loads

- Improves optical quality by optimizing heat-time or heat-profile and preventing overheating of small loads

- Eliminates lost production due to recipe changes

- Eliminates operator errors due to incorrect inputs

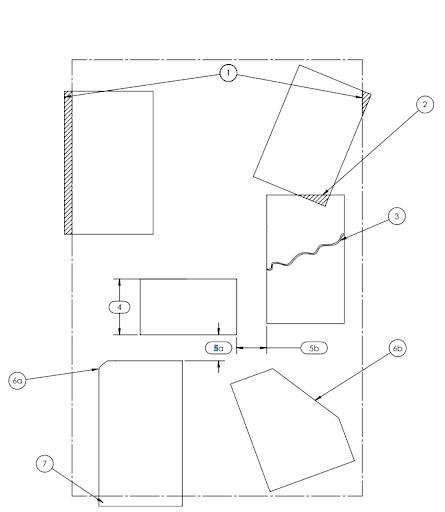

- Detects 7 fault conditions including wide load, part overlap or stacking, broken glass, short part, minimum distance between parts, corner off, and long load.

- Ability to stop a faulty load from moving into the furnace.

- Improves optical quality by optimizing heat-time or heat-profile and preventing overheating of small loads

- Eliminates lost production due to recipe changes

- Eliminates operator errors due to incorrect inputs

- Non-contact, real-time measurement of glass size, thickness and low-E coating

- Detects 7 fault conditions including wide load, part overlap or stacking, broken glass, short part, minimum distance between parts, corner off, and long load.

- Ability to stop a faulty load from moving into the furnace.

Typical Load Validator screen

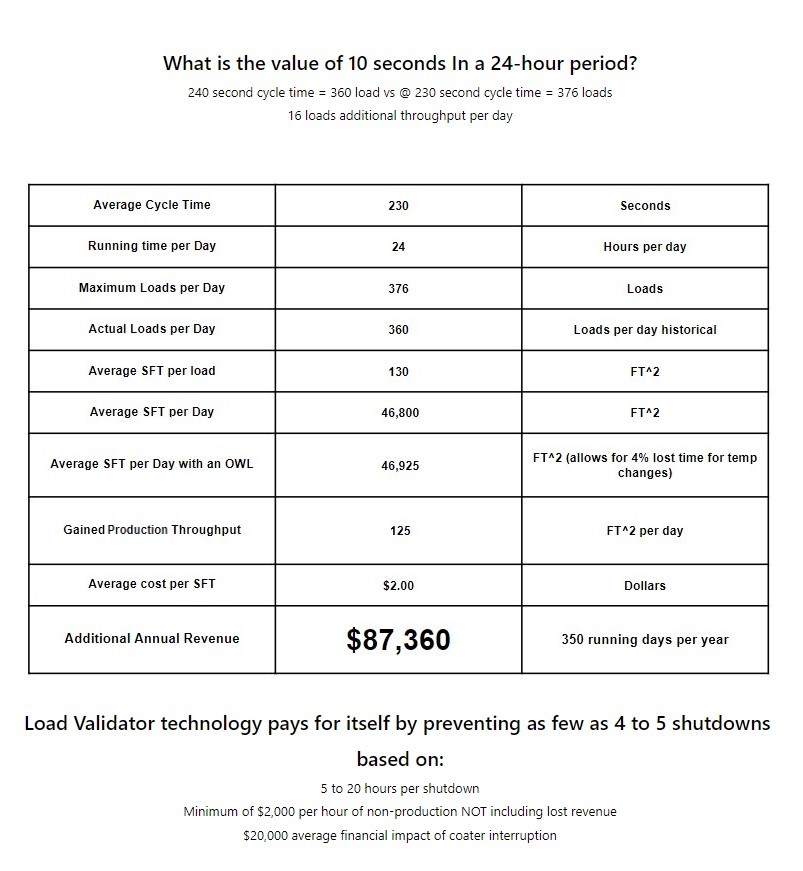

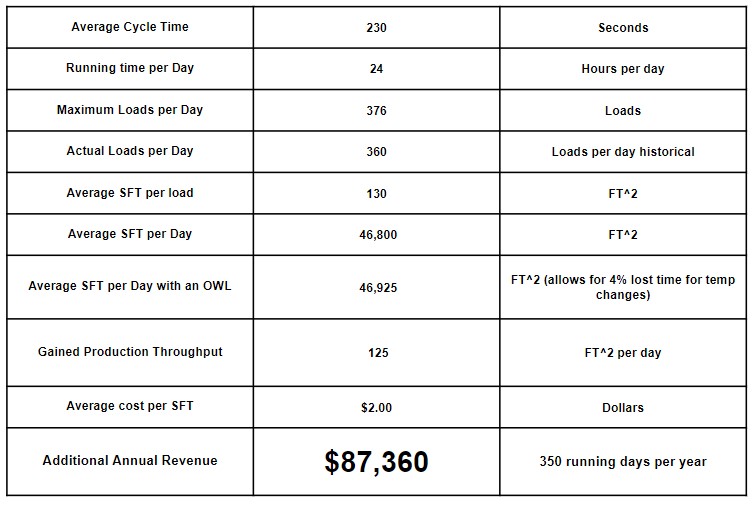

ROI of a LiteSentry Owl

What is the value of 10 seconds In a 24-hour period?

240 second cycle time = 360 load vs @ 230 second cycle time = 376 loads

16 loads additional throughput per day

Load Validator technology pays for itself by preventing as few as 4 to 5 shutdowns based on:

- 5 to 20 hours per shutdown

- Minimum of $2,000 per hour of non-production NOT including lost revenue

- $20,000 average financial impact of coater interruption