Osprey Thank you

Thanks for submitting the form. Our Sales team will get back to you soon.

Thanks for submitting the form. Our Sales team will get back to you soon.

Thanks for submitting the form. Our Sales team will get back to you soon.

Thanks for submitting the form. Our Sales team will get back to you soon.

Introducing the NEW BowScanner Deflection Measurement for Minimizing Breakage Risk and Downtime Introducing the BowScanner, LiteSentry-Softsolution’s […]

TS Series of Thickness & Coating Sensors TS Series of Thickness & Coating Sensors mounted on […]

LOAD VALIDATOR™ GEOMETRY + FAULT DETECTION SYSTEM FOR GLASS The Load Validator™ provides an accurate, repeatable, […]

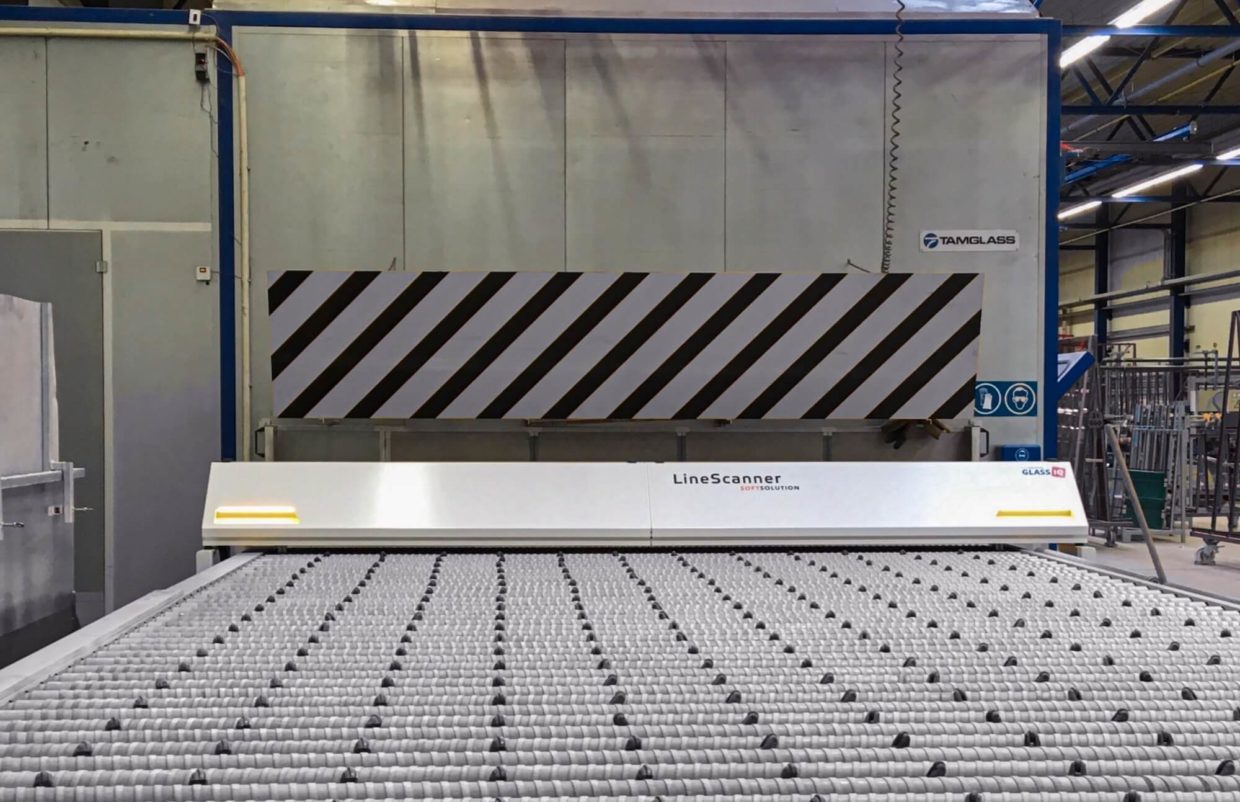

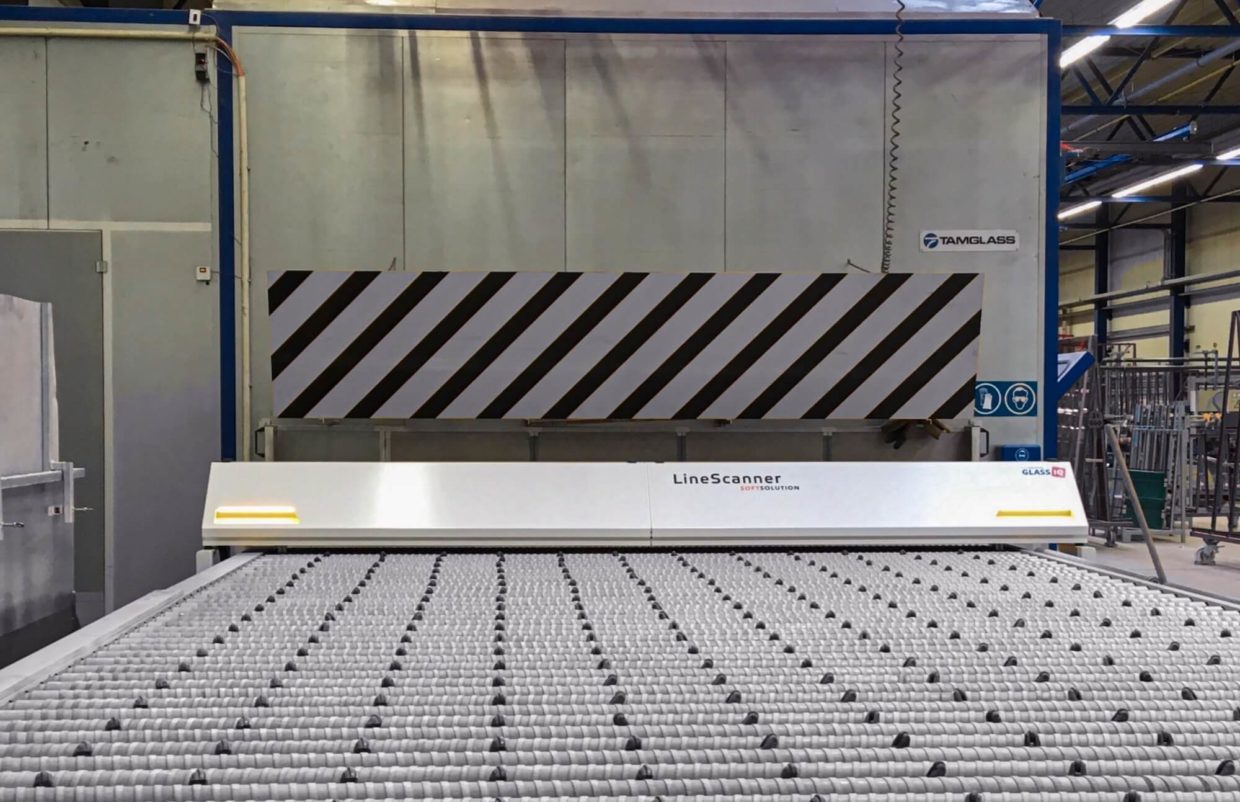

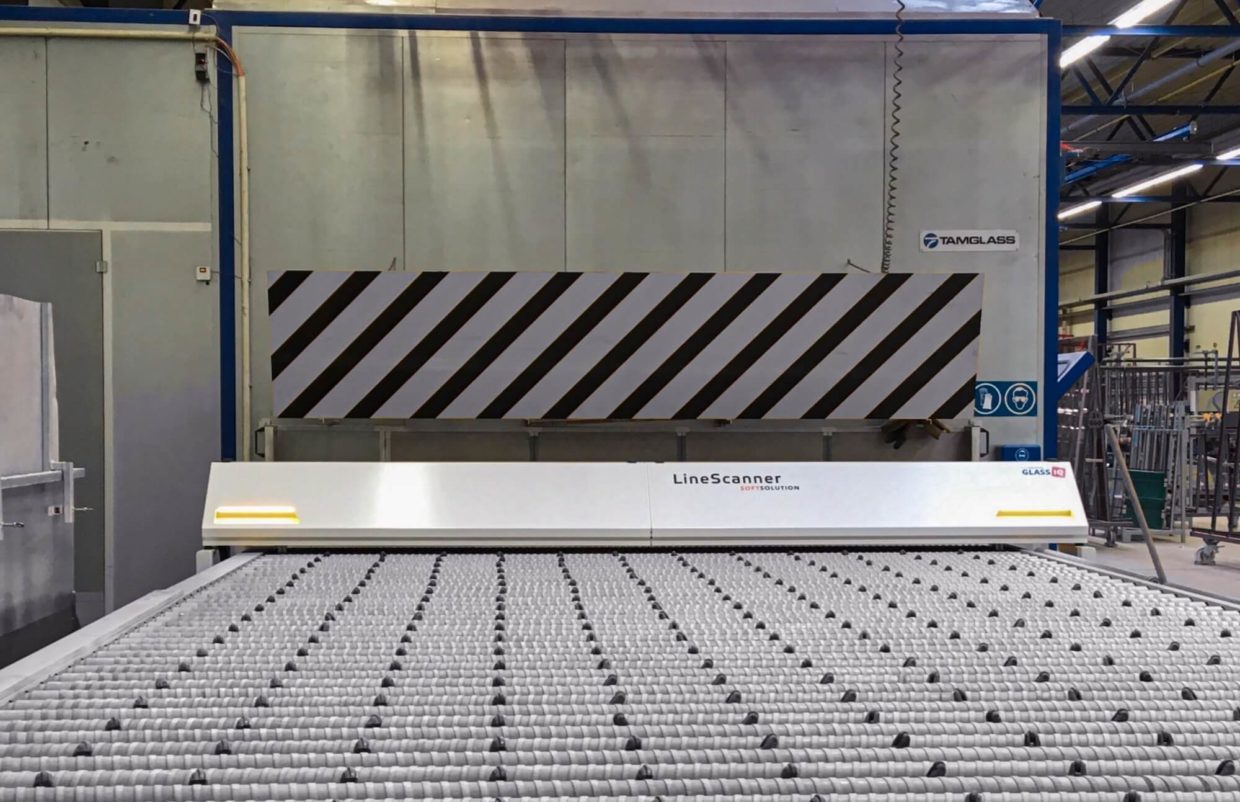

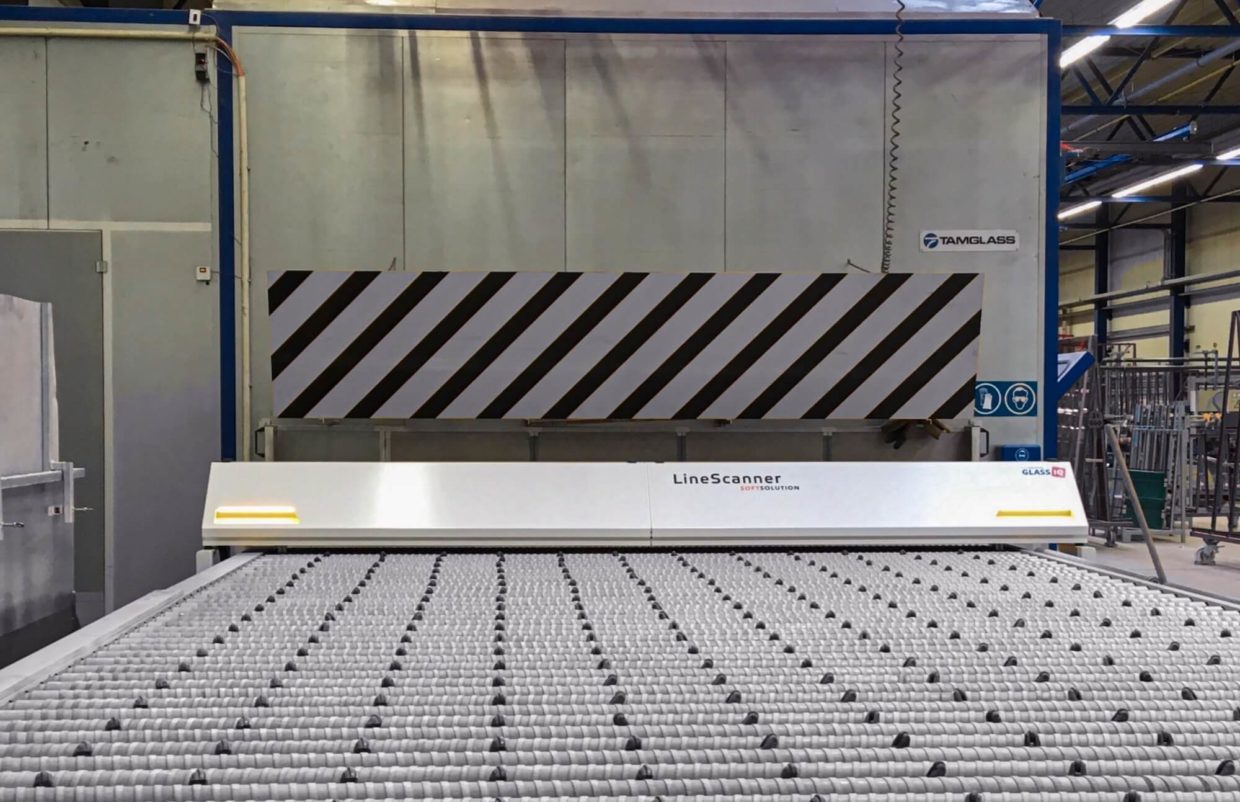

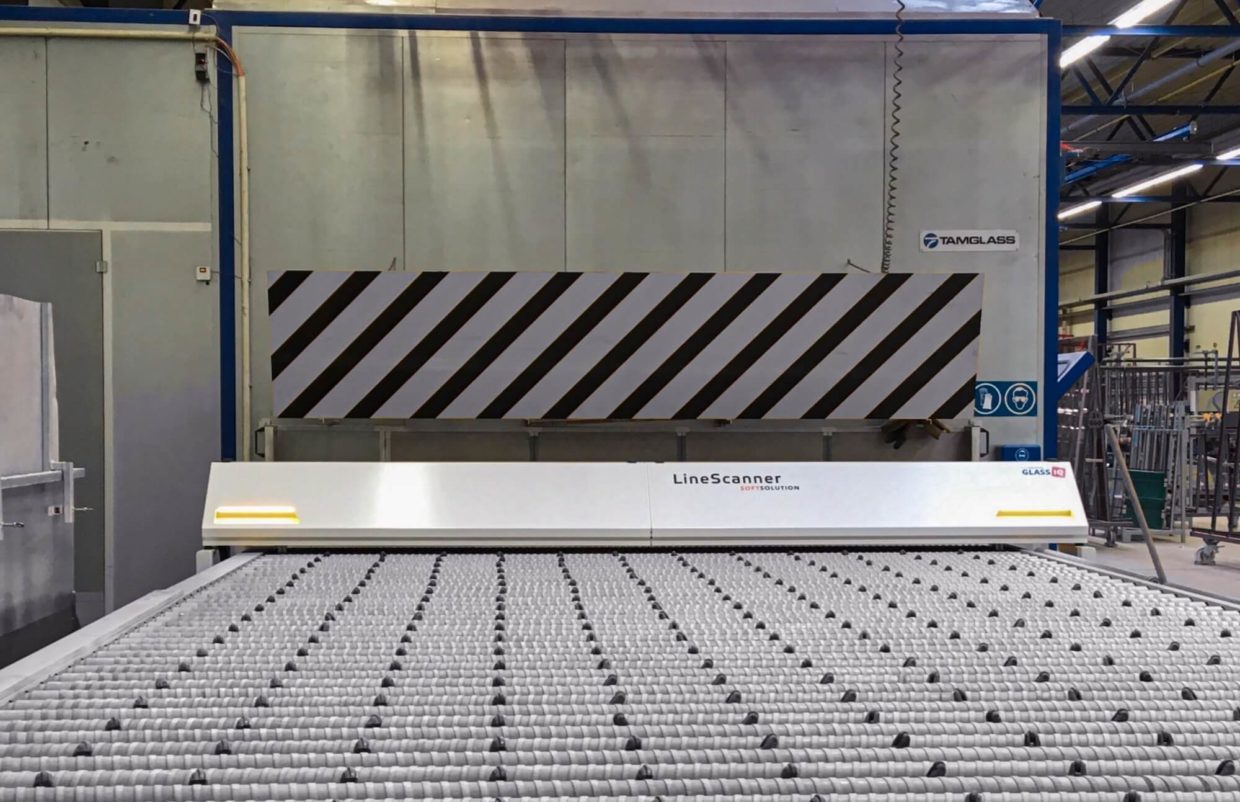

LineScanner Reflection Detecting white haze on tempered glasses. White haze has been a hot topic in […]

TemperQC™ Complete Tempering Quality Control System for Glass TemperQC™ integrates LiteSentry® Systems and 3rd party equipment […]

Hawk® 4 Scratch + Defect Inspection System for Glass The Hawk® Scratch + Defect Inspection system for […]

Owl 5 Glass Furnace Optimization System The Owl 5 transmits data to the furnace control system […]

Osprey® 10 Advance Inspection Systems for Glass LiteSentry’s revolutionary Osprey® 10 advance inspection systems include the […]

Virtual Digitizing – Digitize Templates Digital object data capture with maximum precision VirtualDigitizing – a software […]

CulletScanner Automatic Fragmentation Image Analysis with optional anisotropy and edge stress function The CulletScanner from Softsolution […]

LineScanner High-precision scanning technology for quality inspection of glass The LineScanner is the solution for all […]