Glassquality

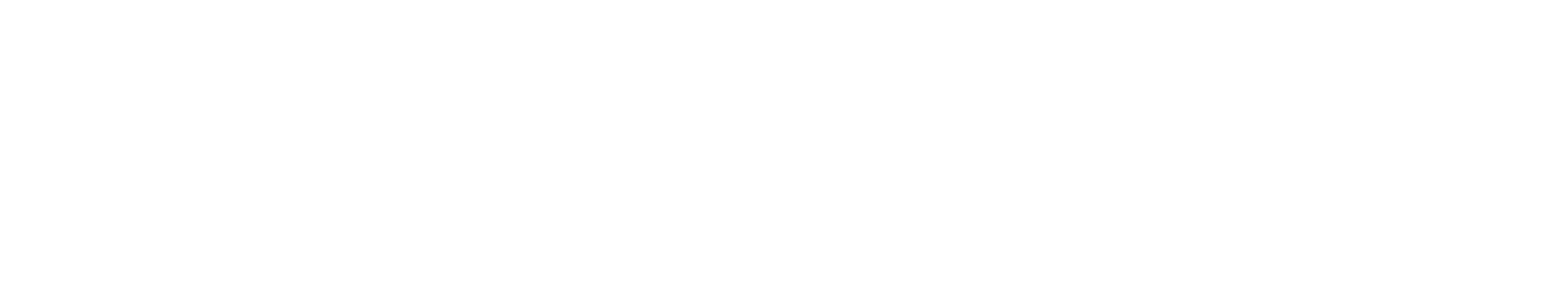

See our products in action in the production line.

Start herePROJECTS WE ARE PROUD OF

Every customer project is unique and that’s how we see the cooperation with our customers. Innovation and the consistent quality of our products are the driving force behind what we do – today, tomorrow and in the future.

We are proud to have implemented a wide variety of projects with renowned companies in the glass industry worldwide. Trust connects and this is not only evident in our dealings with our customers, but also with our national and international partners who stand for our automated quality assurance systems worldwide.

The leaders in inspection, process control and

automatic glass quality assurance systems join forces

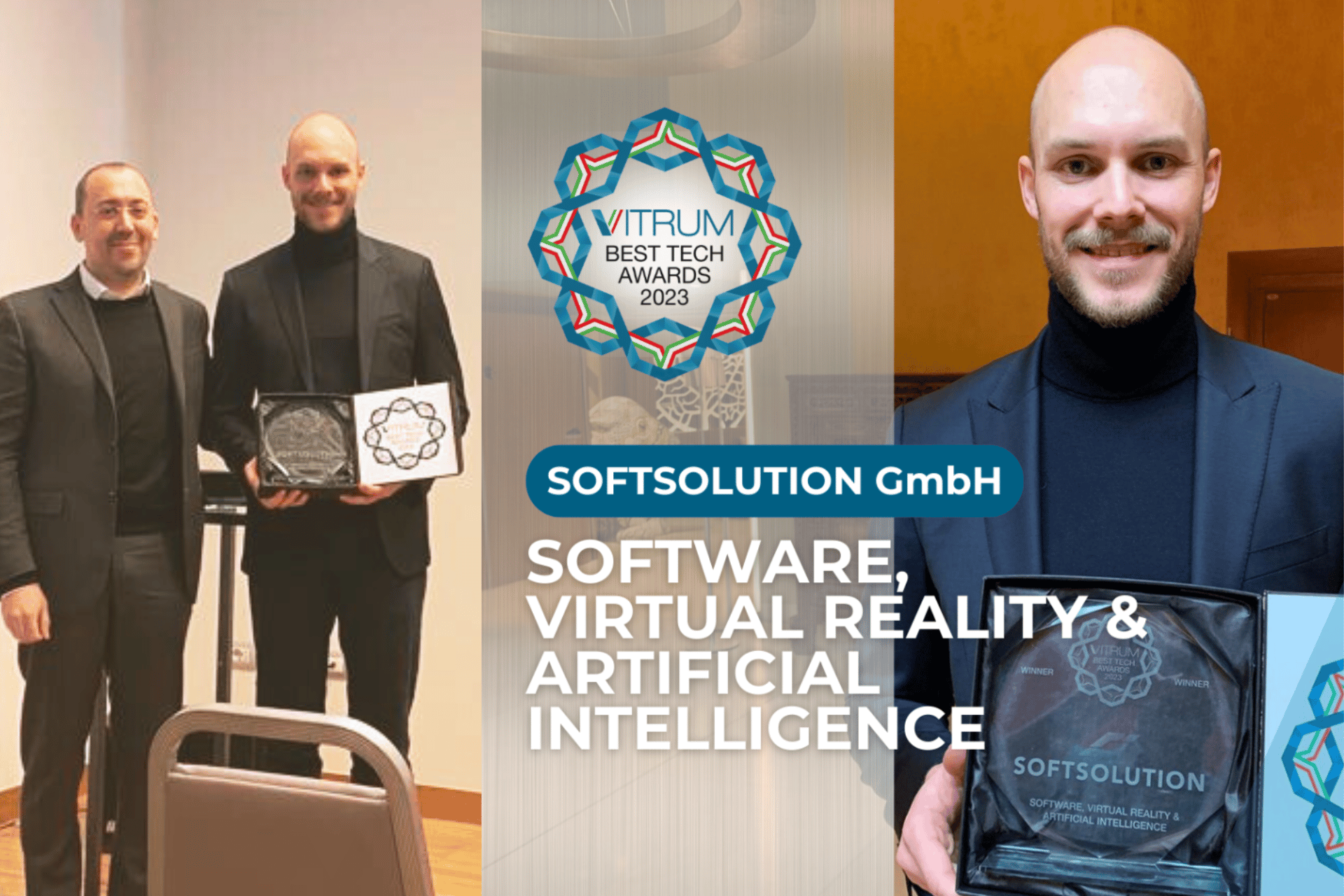

LiteSentry – Softsolution, are pleased to announce a new partnership to support both companies’ long-term growth and success. LiteSentry – Softsolution enhance their ability to respond to customer needs with more localized resources, improve end users’ access to new technology, and accelerate new product development.

At the locations in Austria and in the USA, the two partners score in the installation, service and support segments with higher availability, fast response times and short distances to the customer.

Both LiteSentry and Softsolution have products with a wide range of applications in quality fields of application in quality assurance. As a result of the merger, the product portfolio in the respective markets will be expanded, on the one hand in the area of scanner technology and on the other hand, in camera-based solutions.

Softsolution will continue to operate in its current location in Waidhofen an der Ybbs, Austria.

WHERE ULTIMATE INSPECTION TECHNOLOGY IS BORN

Application Areas

Glass is one of mankind’s oldest materials – versatile, as robust as it is fragile. With our quality assurance systems it is possible to test a wide range of glasses for different applications, which will later be used in industry, research, construction or private households: fully automated, reliable and with absolutely unique technologies from LiteSentry – Softsolution.

New Products and Technologies

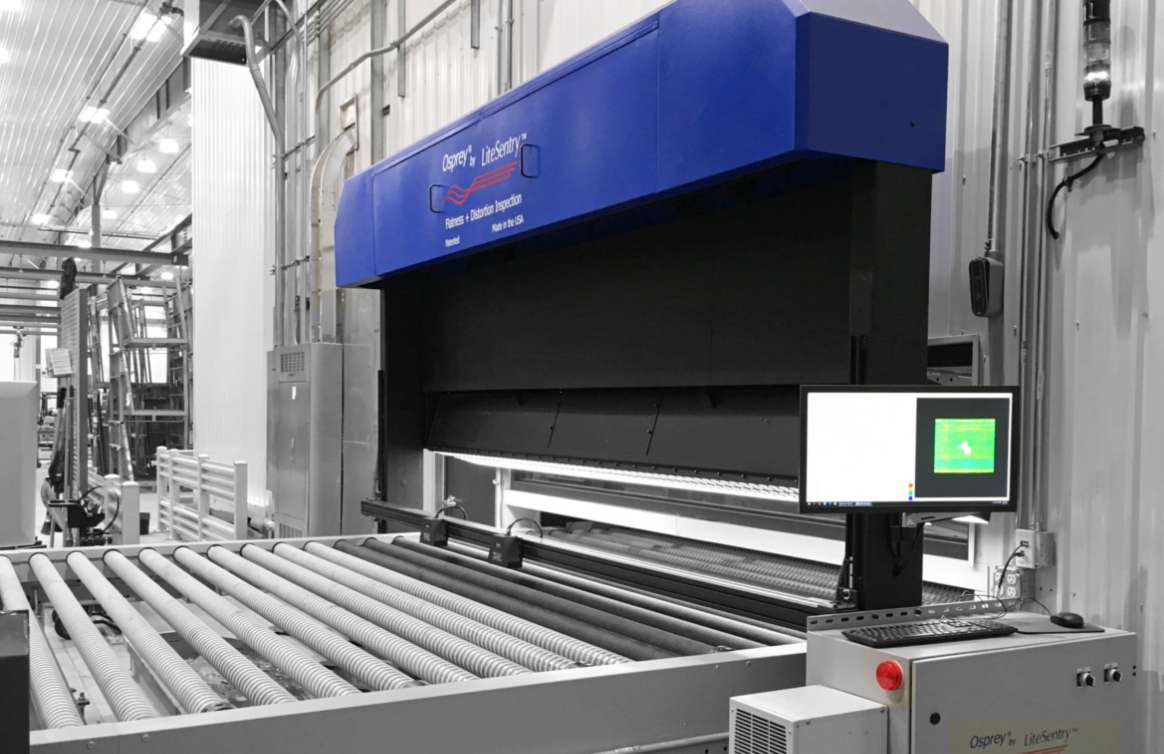

Osprey 10® Inspection System by LiteSentry

Featuring the only optical technology that measures all forms of distortion.

Learn more

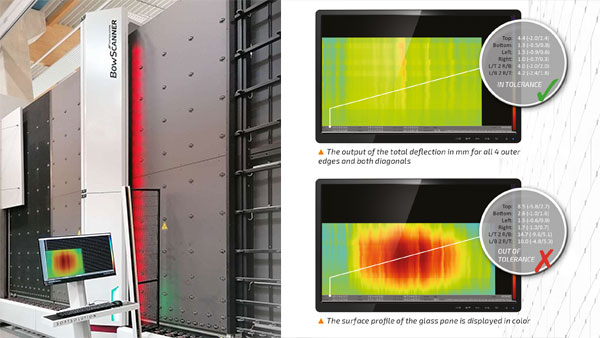

LineScanner by Softsolution

All in one quality inspection with worldwide unique real scanning technology

Learn more

Owl® 5 by LiteSentry

Recipe Selection + Fault Detection System

Our popular optical system, the Owl™ 5 increases throughput and efficiency by detecting faults at the start and optimizing your recipe selection and furnace control.

VirtualDigitizing by Softsolution

A software application for flexible digitization solutions for templates that can be used easily and quickly in any industry.

Learn more

Contact Us

3080

Glass Quality Inspection Systems installed worldwide

LiteSentry™ designs and manufactures patented inspection technology for the glass, solar PV, and sheet plastic industries.

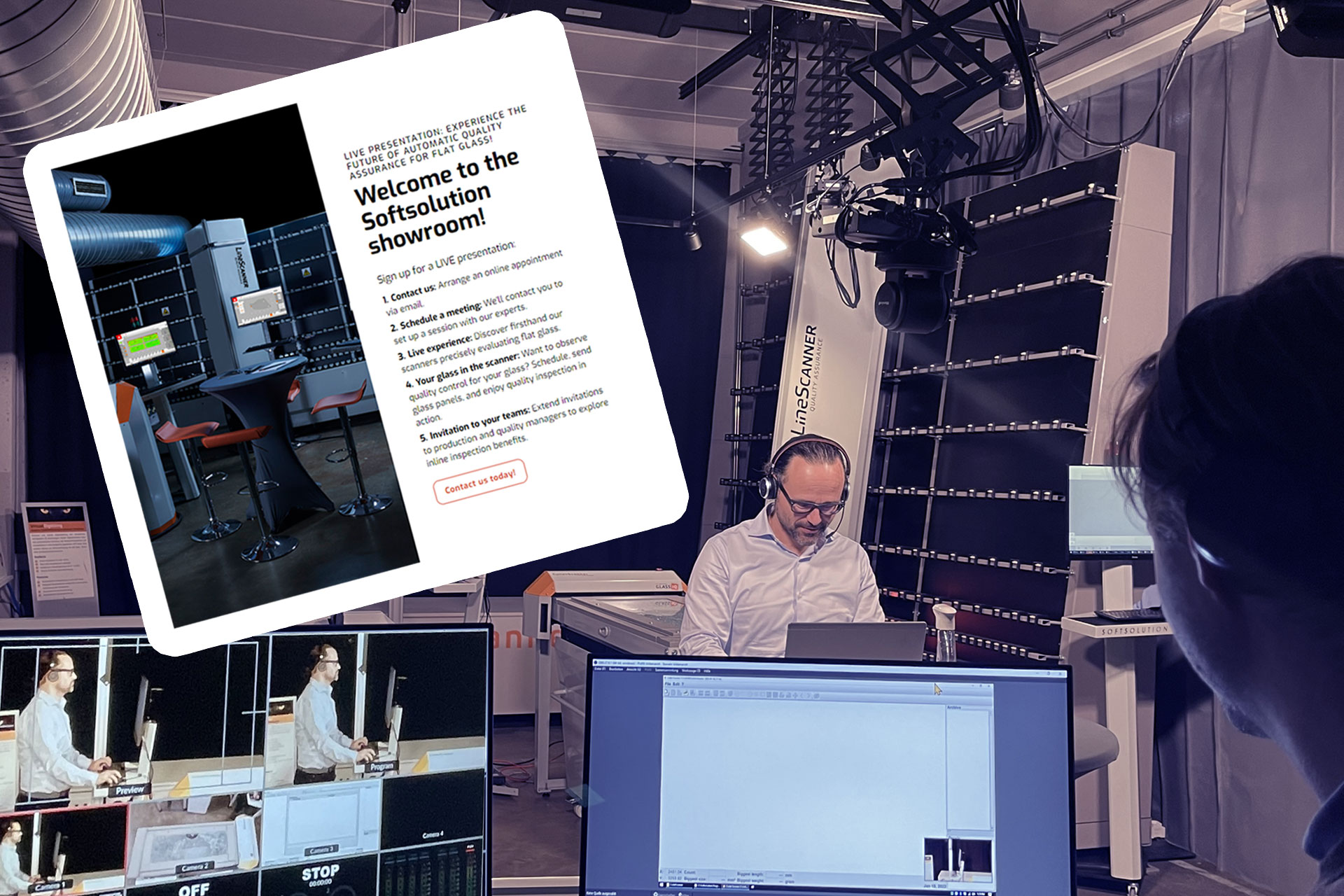

Softsolution is the number one worldwide in the development and production of automated quality assurance systems for the glass industry.

Today, more than 3080 systems combined are in use worldwide. A large network of partners makes our products available on all continents.

Where ultimate inspection technology is born and trusted by these industry leaders